Press release

Mitsubishi Shipbuilding receives BV approval for new LNG fuel system

- Bureau Veritas awards approval in principle for new gas supply system developed for marine 4-stroke dual fuel engines

- New system is suitable for small to mid-sized ships as well as larger vessels

- The approval was confirmed at an award ceremony in Yokohama today

Paris La Défense, October 19th, 2020 – Mitsubishi Shipbuilding Co., Ltd., a part of Mitsubishi Heavy Industries (MHI) Group, has been granted a new approval in principle (AIP) *1 by Bureau Veritas (BV), a world leader in testing, inspection, and certification.

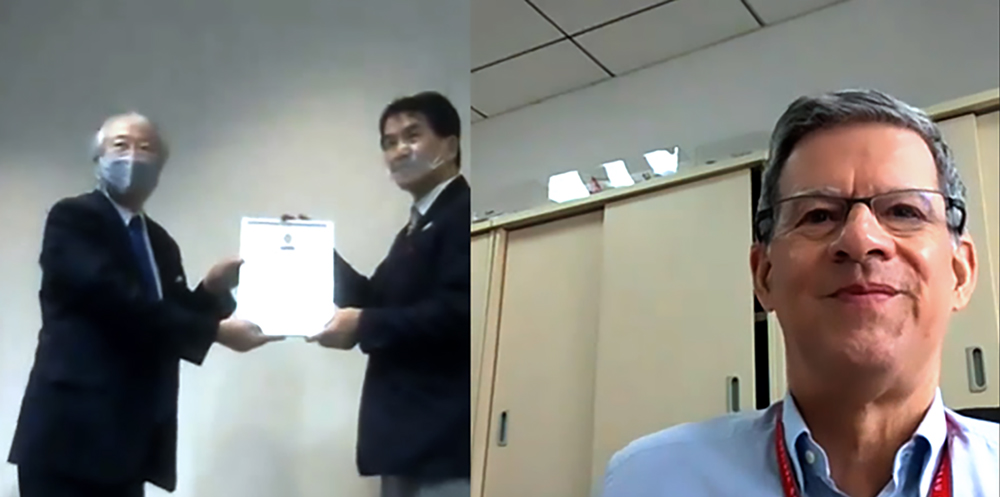

The approval is for a liquefied natural gas (LNG) fuel gas supply system (FGSS) for marine four-stroke dual fuel engines*2. The approval was confirmed in a presentation ceremony at Mitsubishi Shipbuilding’s Headquarters in Yokohama today.

The FGSS comprises an LNG fuel tank, gas supply unit, control systems, and other relevant equipment. The system was developed mainly to be installed on coastal ferries and small to mid-sized cargo ships.

Claude Maillot, Bureau Veritas Senior Vice President, North Asia, who presented the AiP certificate by a video call from Shanghai, commenting today, said: ‘This new system has received BV’s approval in principle recognizing that Mitsubishi Shipbuilding has clearly demonstrated that the new system meets our class rules and standards for gas safety and regulatory compliance. I congratulate Mitsubishi Shipbuilding – it is their deep experience and knowledge, acquired through decades of LNG carrier construction and technical development, that have enabled them to develop this innovative new system.’

Left to right: Kazuo Yamashita - BV BL Manager, Naoki Ueda - Mitsubishi Shipbuilding Executive Vice-President, Claude Maillot - Bureau Veritas Senior Vice President, North Asia

The FGSS will use small size ‘vacuum-insulated’ type containment tanks with a double shell structure that ensures high heat insulation and also allows the external cylinder of the tank to remain at normal temperatures. This simplifies the support structure requirements for the tank and reduces installation work. Furthermore, the Tank Connection Space*3 is also designed to reduce space, operational, and maintenance requirements.

Maillot concluded: ‘Innovations like these are helping drive the industry towards better environmental and operational performance – while reducing risk. Sharing our LNG expertise, we are very proud to be able to support Mitsubishi Shipbuilding in realizing their ambitions.’

Read Mitsubishi Shipbuilding’s media release

Notes

*1: Approval in Principle (AIP) indicates that a certification body has reviewed the basic design and confirmed that it meets the technical requirements and standards for safety. The inspection of this system was conducted based on the IGF Code*4 with which compliance is required when using LNG fuel, and BV’s ship classification regulations.

*2: A Marine four-stroke dual fuel engine is an engine fitted mainly in small and mid-sized ships and is able to use both conventional heavy oil and natural gas as fuel.

*3: Tank Connection Space is a space surrounding all tank connections and tank valves. It is required under the IGF Code for tanks with such connections in enclosed spaces.

*4: The International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) is an international regulation stipulating the safety requirements for ships using LNG and other fuels with low flashpoints.